Group Web Site: Advanced Metals Processing

General Group Overview

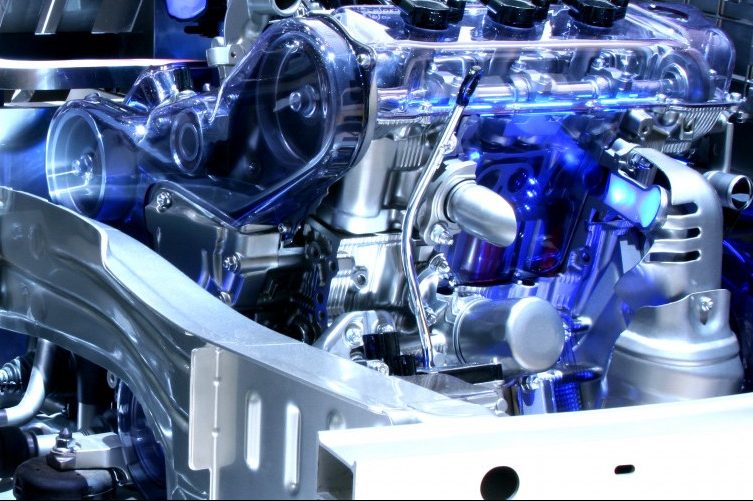

The Advanced Metals Processing research group conducts applied and fundamental research in many areas dealing with advanced metal alloys and their processing with a particular focus on light metal alloys intended for critical applications in the automotive and aerospace sectors.

The demand to reduce emissions in the transportation sector represents a significant challenge that will require development across a broad range of technologies including advances in engine and propulsion technology and the increased used of high-performance light weight structural alloys and materials. In terms of advanced materials, the companies that will lead this revolution will fully embrace advanced process modelling as a means of complementing their in-house experientially-based design capabilities and rapidly adopt new technologies that lie on the horizon. Our approach stresses working in close partnership with industry leaders to develop and implement these models. This entails using commercial software packages as a platform for developing quantitatively accurate and highly specialized models. Areas of specialization include: electron beam and plasma-based melting and casting of titanium alloys; and, advanced die-casting of aluminum automotive parts. These models are validated against measurements conducted in both the industrial and laboratory settings. Recently, we have begun a program on electron beam-based additive manufacturing (3D printing), which will build on our experience in titanium alloy processing. Key industrial partners include Titanium Metals Corp. a world-leading producer of titanium alloys, CITIC Dicastal, the world leading producer of automotive wheels and Toyota. We are actively seeking highly motivated graduate students and post-doctoral fellows. This is an exciting area that will see tremendous advances in the next 10 years. We look forward to hearing from you.

The Advanced Metals group is one of 5 elite clusters that form the Advanced Manufacturing for Global Mobility Institute (AMGM), which is the catalyst for the future growth, and success of advanced manufacturing in Canada.

Key Impact Areas

- Material Characterization

- Die and Tool Life

- Novel Casting Processes

- Additive Manufacturing

- Thermal Processes

- Residual Stress

- Virtual Manufacturing

- Cast Product Performance

Advanced Metals Processing Equipment

AMPEL houses over $16million worth of equipment, built to industry’s specifications.

We have 2 Laboratories and 5 Workshops where we can heat, shape, finish, measure, test and analyse a variety of metal parts and components.

To see the laboratories, workshops and equipment, please see here:

UBC Centre for Metallurgical Process Engineering

Faculty